The double-digit million euro investment in a new inductive single-bar tempering plant will not only enable GMH to tap into new markets such as the wind power sector, but also further reduce the carbon footprint of its products as it steps up its green steel production.

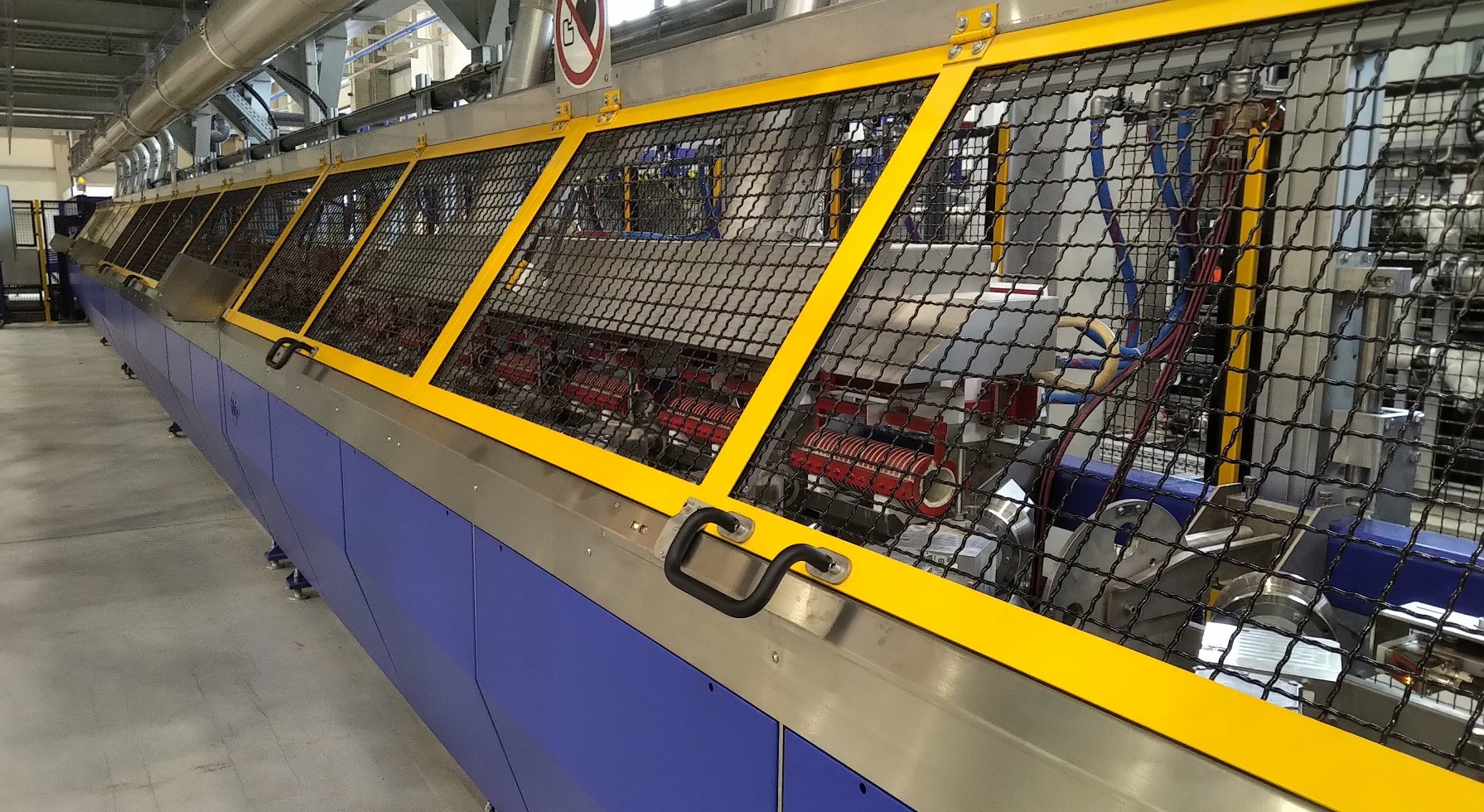

The Georgsmarienhütte plant, the GMH Gruppe’s largest production site, is gearing up for the future. The company is investing around 21.5 million euros in an inductive single-bar tempering system (EVA), which will be installed in two stages. It will operate fully automatically and thus increase occupational safety at the same time. This new method will replace a labour-intensive and risky process step that involves individual steel bars had to be partially reworked manually, right after heating.

The special feature of this type of plant units is above all that it is run by electricity. This offers two major advantages over conventional gas-powered plants. Steel properties are significantly improved in just one step as a result of a novel inductive heat treatment process. The use of electricity also ensures a major reduction in the product carbon footprint (PCF) of the components manufactured by GMH, as well as the end products in which they are installed. The plant unit is designed to run on up to 100 percent green electricity.

EVA gives the GMH Group the ability to produce highly sophisticated induction quenched and tempered green steel that is optimally tailored to applications outside the automotive sector. These include, for example, bolts and connecting elements for wind turbines or conveyor systems in industrial applications.

For this project, which will save around 2,800 metric tons of CO2 at the Georgsmarienhütte site alone by switching from natural gas to (eco)electricity, the GMH Group has received funding from the German Federal Ministry of Economics amounting to around 880,000 euros. The funding decision for EVA was the first of its kind issued by the ministry as part of its “Decarbonisation in Industry” programme. It also covers other energy-intensive sectors as well as the steel industry.

“We cannot serve all customer requests with the capacities of the existing plants. We will now change that so we can secure additional business opportunities. According to estimates, around 30,000 new wind turbines will be needed in Germany alone by 2030,” says Dr. Alexander Becker, CEO of GMH Group. “Each individual wind turbine requires around 13 tons of steel for screws and fasteners. Extrapolated to the total demand, this results in a potential of more than 60,000 tons of steel per year. With this first of two new single-bar tempering plants, we are creating the basis for exploiting this enormous market potential for ourselves and playing an important role in this future market.”

Commissioning of the first plant is scheduled for the end of the year, with completion of the second stage next year. As a pioneer in steel production with electric arc furnaces, the GMH Gruppe is thus setting another important milestone on the road to climate neutrality. With an additional investment programme that was also approved, one of Europe's leading suppliers of bar, rolled and crude steel will be bringing its production facilities up to a new level in the coming years – in some cases setting new standards in steel production. In addition to the inductive single-bar tempering line, numerous other projects have already been initiated at several GMH Gruppe companies to drive flexible and sustainable production forward.

Senior Account Manager

Beitrag teilen